WKTEC New Arrival 2 axis Mini CNC Lathe Machine for Metal Processing

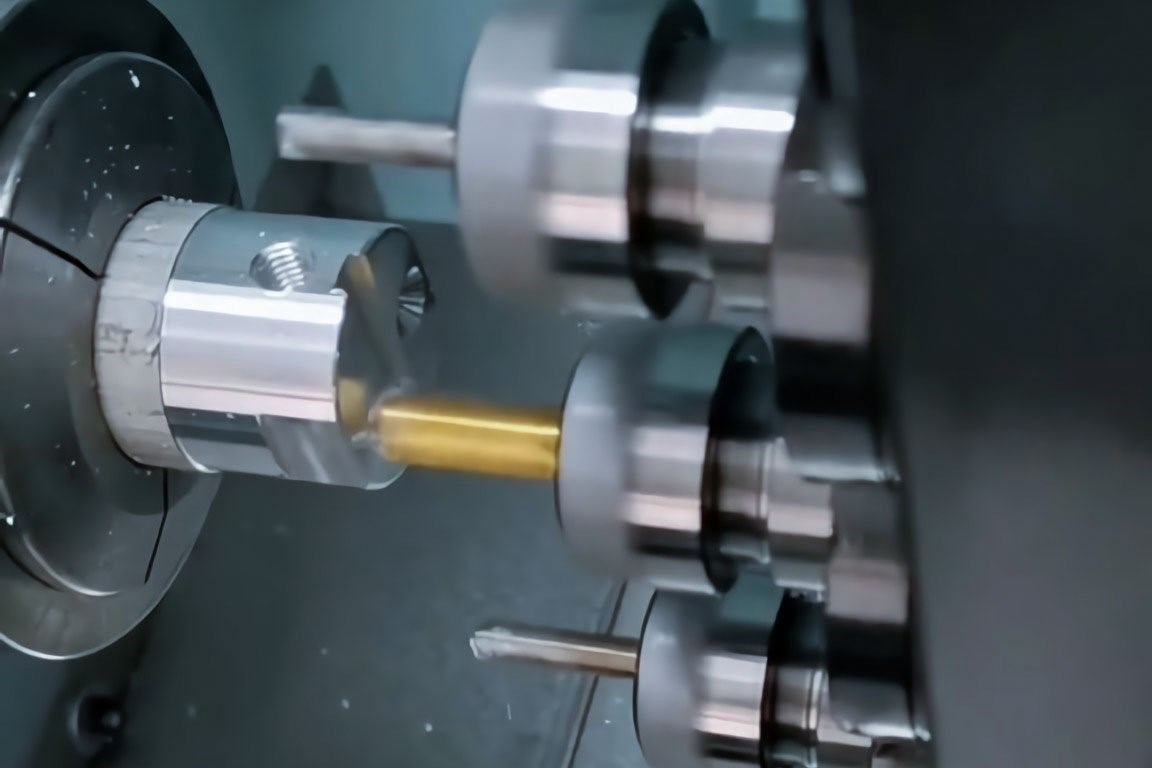

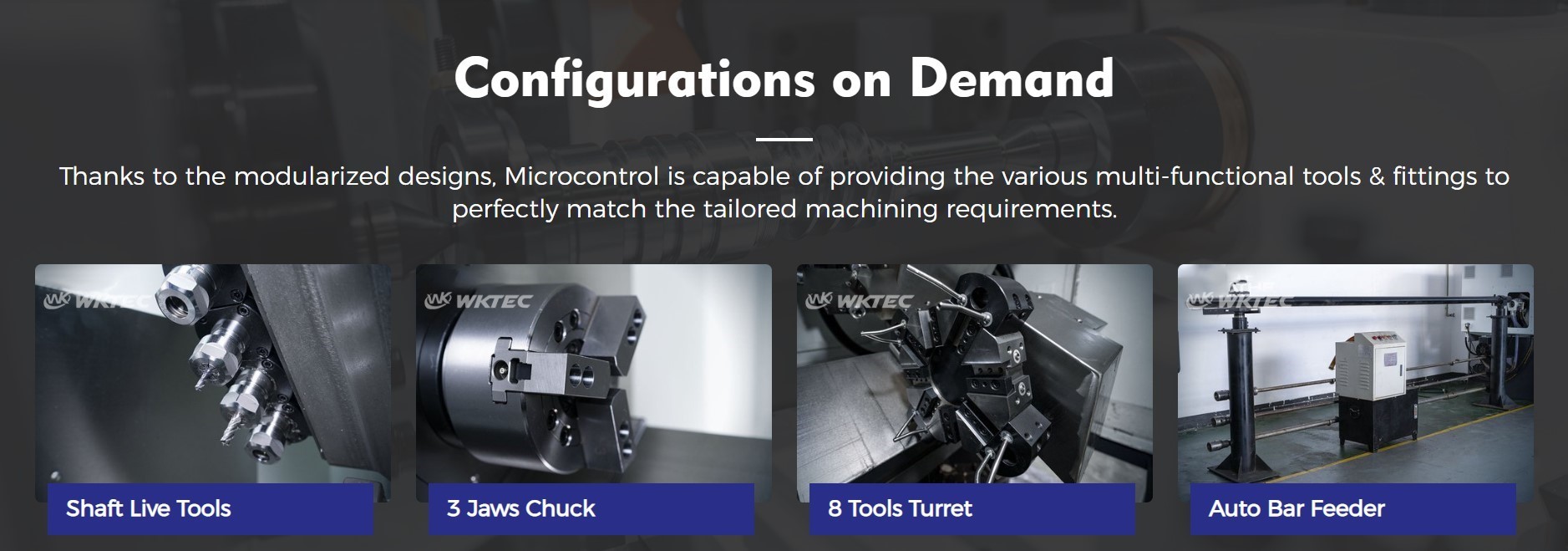

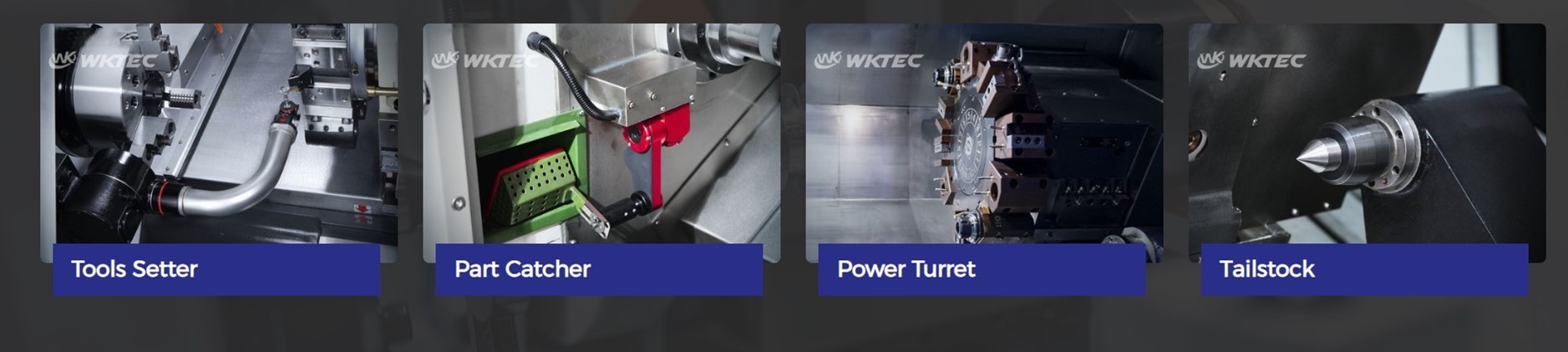

Metal-Cutting CNC Machine Tools, CNC Non-Conventional Machine Tools, Metal-Forming CNC Machine Tools LC-36 comes with a high-speed spindle with 5,000 RPM, mini metal lathe machine,providing 4-HP powerful output for heavy-duty machining. Thanks to a large work envelope with extensive X/Z travel, it could configure with a wide variety of tools, like side live tooling devices, Y-axis for grooving, drilling, and radial cuts on the OD.

Classification:

CNC Lathe Machine

Keywords:

Hotline:

Product description

Main technical parameters of machine tool;

| Name | CNC lathe model | LC-36 CNC machine | CNC Control System | CNC Control System | Micro-control bus system 630TA |

| Scope of work |

Maximum turning diameter of bed (mm) |

Φ400 |

Servo |

Micro control 23-bit absolute value |

|

|

Maximum machining diameter (mm) |

Φ200 |

Hydraulic system |

Electric power of hydraulic system |

750W |

|

|

Maximum machining length (mm) |

100 |

Tank capacity |

40L |

||

|

Bed saddle and horizontal inclination |

35° |

Hydraulic pump pressure |

70Kgf/cm2 |

||

|

Principal axis |

Spindle Motor Power (Kw) |

3.7Kw |

Water box |

Large lift soft cooling water pump |

120W lift 4m flow 50L/min |

|

Spindle Nose Taper |

A2-4 |

lubrication |

Automatic lubrication |

1.5L centralized quantitative automatic lubrication system |

|

|

Spindle type |

Sleeve spindle unit |

Transmission components |

Main shaft bearing |

P4 |

|

|

Diameter of main shaft through hole (mm) |

Φ45 |

Ball screw |

X:32*10(SHAC, Taiwan) |

||

|

Spindle speed range (r/min) |

0-5000 |

Guide |

X:25 Z:30 |

||

|

Spindle accuracy (mm) |

Shaft end radial runout ≤ 0.005 |

Repetitive positioning accuracy (mm) |

±0.003 |

||

|

Clamping device |

Hydraulic collet |

1 Individual |

Positioning Accuracy (mm) |

±0.005 |

|

|

Hydro-cylinder |

Swing cylinder |

Screw bearing |

SKF bearing |

||

|

Axis |

X-Axis (mm) |

700 |

Voltage |

AC three-phase power |

380V 50Hz |

|

Z-Axis (mm) |

250 |

Tricolor lamp |

Red light |

Generate alarm |

|

|

X-axis feed motor (N.M) |

4 |

Yellow light |

Position in readiness |

||

|

Z-axis feed motor (N.M) |

4 |

Green light |

Running state |

||

|

Maximum moving speed of X-axis (m/min) |

25 |

Electrical lamps |

Electric relay |

Fender, Italy |

|

|

Maximum moving speed of Z-axis (m/min) |

25 |

AC contactor |

Chint |

||

|

Blade adapter |

Tool holder form |

Cutter arrangement |

Working light |

LED |

|

|

Number of cutters |

-- |

Electrical capacity (A) |

|||

|

Specification of outer diameter and end face tool handle |

16 |

Weight |

Overall dimension (mm) |

1880*1400*1550 |

|

|

Diameter of inner hole cutterbed (mm) |

20 |

Machine weight (Kg) |

1500Kg |

||

|

Number of cutterbed |

6 |

|

Application

LC-36 provides both two-axis high-precision turning and the possibilities of complex multi-tasking operations like hard turning, taper turning, parting, facing, boring, grooving, reaming, drilling, threading, knurling, etc. Easily handle the bar materials with diameter max. Φ36 mm or individual workpieces diameter max. Φ350mm (Chuck size max. Φ50mm).

| Case Study

Configuration: LC-36 installs the Hydraulic chuck、Hydraulic collect, Y-Axis Side Milling Device & End Side Live Tooling Device (4-Tool), and C-axis function* Workpiece: Turning a Φ33 aluminum foundation from Φ36mm bar materials Machining Process: Turning, Facing, Milling, Drilling, Tapping, Parting. Turning Duration: within 40 seconds |

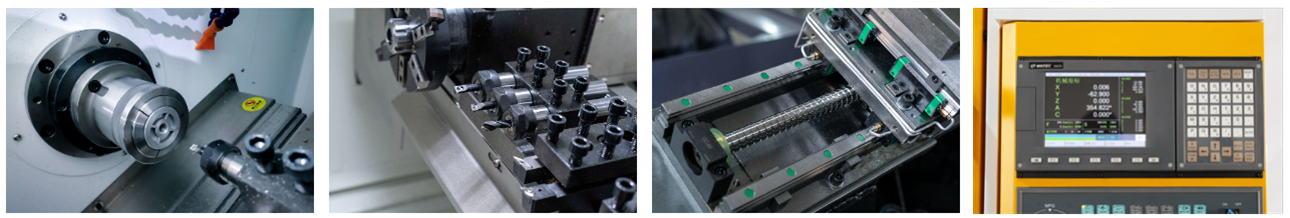

All structural parts of the LC-36 turning machine are made of high-quality cast iron, well-tempered, and stress relief to guarantee a long run of reliability.

Fully enclosed for a waterproof and operational safety machining chamber. This model is designed to achieve a variety of automatic solutions such as oil bath, air bath, vibration plate, and auto-loading/unloading collaborative with a robotic arm.

LC-36 is outfitted with a rigid 35-degree machine bed, high-accuracy 25-gauge linear guides, and grinding ball screw that contributes to the faster chip removal and running speed.

LC-36 turning machine has a spacious work envelope to equip a bunch of live tooling option that provides multi-axis milling and turning, off-center line Y-axis milling functionality.

The working length of the X-axis reaches 700mm. Gang-type tool highly increases efficiency in one-time machining.

The hydraulic clamping system with a disk brake (opt.) ensures the rigidity for heavy-duty turning & milling and the entire C-Axis 360° control.

Available a variety of lathe holding versions with different spindle bore and chuck sizes.

Product message