2 Axis WKTEC CNC Lathe Machine with Standard Type Screw and Guide Rail, Bearing

Metal-Cutting CNC Machine Tools, CNC Non-Conventional Machine Tools, Metal-Forming CNC Machine Tools.

Classification:

CNC Lathe Machine

Hotline:

Product description

|

name say/call |

Numerical control lathe model |

LC-36 (CNC LATHE) |

system |

numerical control system |

WKTEC 630TA bus system |

|

working range |

Maximum slewing diameter of lathe bed(mm) |

Φ400 |

servo |

Micro-control 23-bit absolute value |

|

|

Maximum machining diameter (mm) |

Φ200 |

hydraulic pressure system |

Electric work of hydraulic system rate |

750W |

|

|

Maximum machining length (mm) |

100 |

fuel tank capacity |

35L |

||

|

Saddle and horizontal inclination |

35° |

Hydraulic pump pressure |

70Kgf/cm2 |

||

|

principal axis |

Spindle motor power (Kw) |

3.7Kw (servo spindle) |

water tank |

Large lift soft cooling water pump |

120W lift 4m flow 50L/min |

|

Spindle nose form |

A2-4 |

lubricate |

Automatic lubricating device |

1.5L centralized quantitative automatic moistening Sliding system |

|

|

Spindle type |

Sleeve spindle unit (Tongfu) |

drive disk assembly |

mainshaft bearing |

P4 grade |

|

|

Diameter of spindle through hole (mm) |

Φ45 |

Ball screw C3 stage |

X:32*10 Z:32*10 |

||

|

Spindle speed range (r/min) |

0-4000 |

Guide rail p level |

X:25 Z:30 |

||

|

Spindle accuracy (mm) |

Radial runout of shaft end ≤ 0.005 Axial movement ≤0.005 |

Re-positioning accuracy (mm) |

±0.003 |

||

|

Clamping device put |

Hydraulic chuck |

one |

Positioning accuracy (mm) |

±0.005 |

|

|

hydrocylinder |

huizhuanyougang |

Screw bearing |

SKF/THT bearing |

||

|

axis |

X-axis limit travel (mm) |

700 |

voltage |

Ac three-phase electricity |

380V 50Hz |

|

Z-axis limit travel (mm) |

250 |

Tricolor lamp |

Red light |

Generate an alarm |

|

|

Y-axis limit travel (mm) |

130 |

Yellow light |

holding state |

||

|

X-axis feed motor (N.M) |

5.4 |

Green light |

running state |

||

|

Z-axis feed motor (N.M) |

six |

|

|

||

|

Y-axis feed motor (N.M) |

3.2 |

|

|

|

|

|

X-axis maximum moving speed (m/min) |

25 |

electricity utensil |

relay |

Omron |

|

|

Z-axis maximum moving speed (m/min) |

25 |

lamps and lanterns |

Ac contactor |

chint |

|

|

Y-axis maximum moving speed (m/min) |

15 |

|

|

|

|

knife rest |

Tool rest form |

Guild Battle Strategy |

Working lamp |

LED |

|

|

Tool number |

-- |

|

|

||

|

Specification of outside diameter and end face shank |

16 |

Shape weight |

Overall dimension (mm) |

1880*1400*1550 |

|

|

Diameter of inner hole tool holder (mm) |

20 |

Machine tool weight (Kg) |

About 1600Kg |

||

|

Number of tool seats |

six |

|

Total power of machine tool |

8KW |

|

|

unit head |

Number of power heads |

three |

|

|

|

|

Power head specification |

ER20 |

||||

|

Power head motor power |

1.2KW |

|

|

|

|

|

Maximum speed of power head |

3000 |

|

|

|

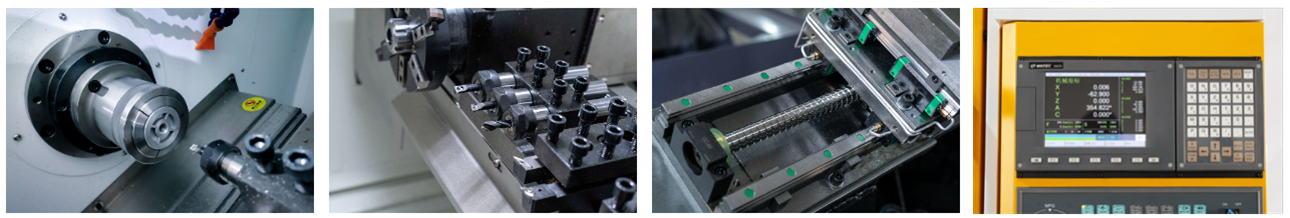

Application

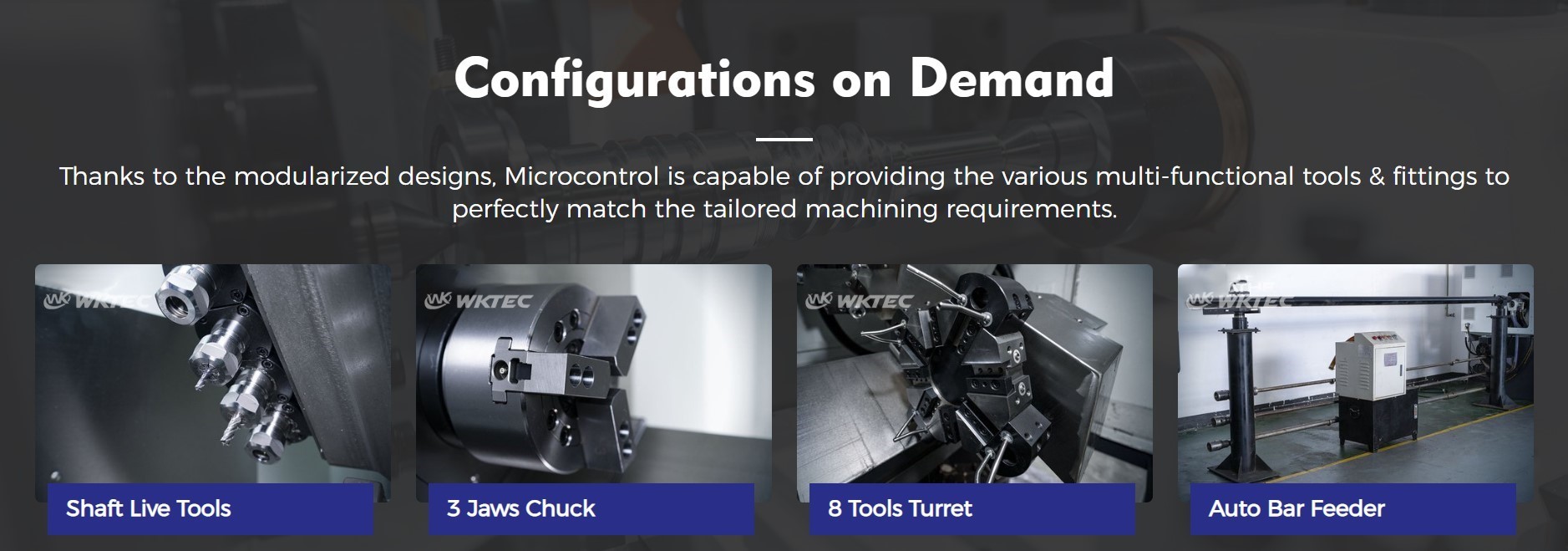

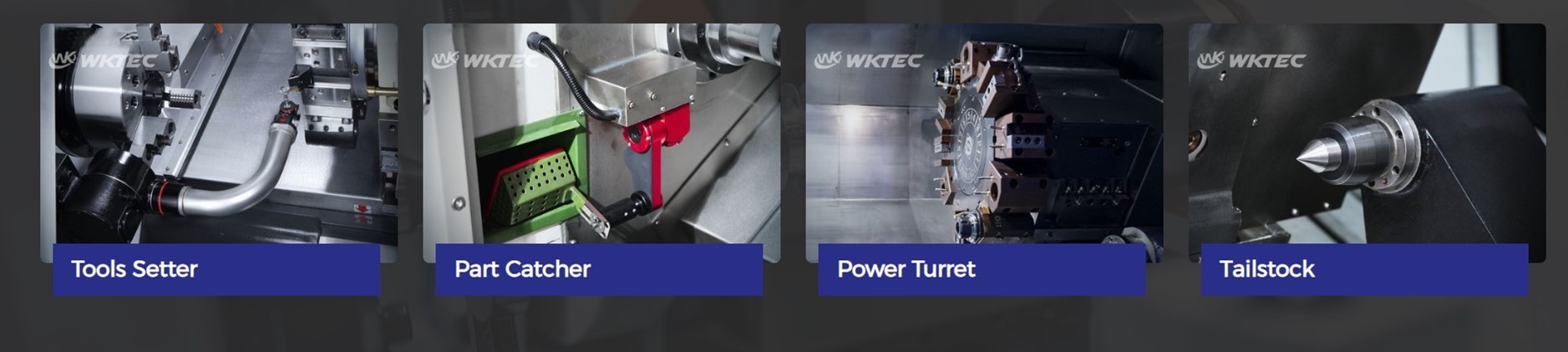

Easily handle the bar materials with diameter max. Φ36 mm or individual workpieces diameter max. Φ350mm (Chuck size max. Φ50mm).provides both two-axis high-precision turning and the possibilities of complex multi-tasking operations like hard turning, taper turning, parting, facing, boring, grooving, reaming, drilling, threading, knurling, etc.

| Case Study Configuration: LC-36 installs the Hydraulic collect, Y-Axis Side Milling Device, and C-axis function* Workpiece: Turning a Φ32 small impeller from Φ32mm brass bar material Machining Process: Turning, threading, Facing, Milling, Parting. Turning Duration: within 30 seconds |

|

The LC-36Y mill-turn machining center has a roomy working envelope with extensive X/Z travel so that more complicated workpieces could be achieved easily.

The LC-36Y mill-turn machining center has a roomy working envelope with extensive X/Z travel so that more complicated workpieces could be achieved easily.

Thanks to the diverse tooling combinations, LC-36Y helps improve machining accuracy while reducing clamping times.

X-axis travel to 700mm and Z-axis to 250mm reducing the lathe footprint and enhancing stability and ease of chip removal.

Complex machining, such as turning and milling, can complete most of the process at one-time clamping, considerably reducing the processing time.

The main spindle is with C-axis function, high speed, high precision, and low vibration which can make the workpiece precise. Each spindle bearing assembly was tested for dynamic balance before installation to ensure high-speed running stability.

CNC turning and milling machine Equips with Taiwan 32mm ball screw rod rail and 32mm linear guideway to provide precision and low vibration tool carriage movement.

Equips with auto lubrication system to ensure transmission system smoothly and long-lived.

Robust hydraulic collet chuck can hold bars up to Φ35mm and a single workpiece up to Φ50mm.

Automatic solutions are available for the bar feeder, gantry loading device, or robotic arms.

Next page

Next page

Product message