CNC lathe with automatic feeding machine

WKTEC cnc automatic lathe High Speed And High Precision Parts Machining Center China Cnc Machine

Classification:

CNC Lathe Machine

Hotline:

Product description

Main technical parameters of machine tool;

|

|

|

|

|

|

|

|

name |

CNC lathe model |

LC-36(Integral casting) |

CNC Control System |

CNC Control System |

Micro-control bus system 630TA |

|

Scope of work |

Maximum turning diameter of bed (mm) |

Φ400 |

servo |

Micro control 23-bit absolute value |

|

|

Maximum machining diameter (mm) |

Φ200 |

Hydraulic system |

Electric power of hydraulic system |

750W |

|

|

Maximum machining length (mm) |

100 |

Tank capacity |

40L |

||

|

Bed saddle and horizontal inclination |

35° |

Hydraulic pump pressure |

70Kgf/cm2 |

||

|

principal axis |

Spindle Motor Power (Kw) |

3.7Kw |

water box |

Large lift soft cooling water pump |

120W lift 4m flow 50L/min |

|

Spindle Nose Taper |

A2-4 |

lubrication |

Automatic lubrication device |

1.5L centralized quantitative automatic lubrication system |

|

|

Spindle type |

Sleeve spindle unit |

Transmission components |

Main shaft bearing |

P4 |

|

|

Diameter of main shaft through hole (mm) |

Φ45 |

ball screw |

X:32*10(SHAC, Taiwan) Z:32*10(SHAC, Taiwan) |

||

|

Spindle speed range (r/min) |

0-4000 |

guide |

X:25 Z:30 |

||

|

Spindle accuracy (mm) |

Shaft end radial runout ≤ 0.005 Axial displacement ≤ 0.005 |

Repetitive positioning accuracy (mm) |

±0.003 |

||

|

Clamping device |

Hydraulic collet |

1 individual |

Positioning Accuracy (mm) |

±0.005 |

|

|

hydro-cylinder |

Swing cylinder |

Screw bearing |

SKF bearing |

||

|

Axis |

X-Axis (mm) |

700 |

Voltage |

AC three-phase power |

380V 50Hz |

|

Z-Axis (mm) |

250 |

Tricolor lamp |

Red light |

Generate alarm |

|

|

X-axis feed motor (N.M) |

4 |

Yellow light |

Position in readiness |

||

|

Z-axis feed motor (N.M) |

4 |

Green light |

running state |

||

|

Maximum moving speed of X-axis (m/min) |

25 |

Electrical lamps |

electric relay |

Fender, Italy |

|

|

Maximum moving speed of Z-axis (m/min) |

25 |

AC contactor |

chint |

||

|

blade adapter |

Tool holder form |

Cutter arrangement |

Working light |

LED |

|

|

Number of cutters |

-- |

Electrical capacity (A) |

|

||

|

Specification of outer diameter and end face tool handle |

16 |

weight |

Overall dimension (mm) |

1880*1400*1550 |

|

|

Diameter of inner hole cutterbed (mm) |

20 |

Machine weight (Kg) |

1500Kg |

||

|

Number of cutterbed |

6 |

|

|

|

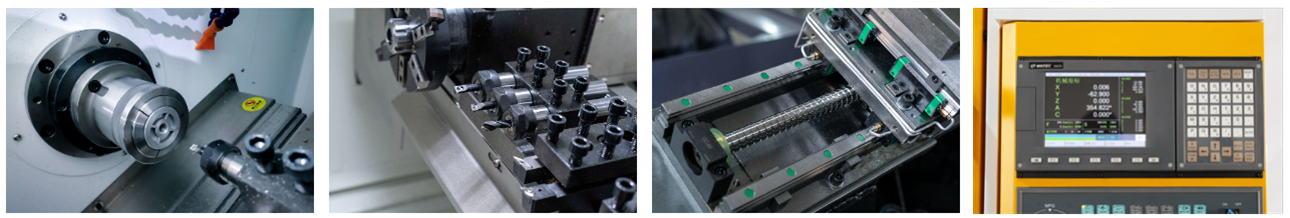

1. The bed is made of high-strength cast iron, with compact structure, good strength, proper hardness and low friction coefficient. The bed has a 35 degree slope. The integral box structure greatly enhances the overall rigidity and stability of the machine tool, and has the function of shock absorption, reduces the tool loss, improves the quality of the workpiece, and provides users with the guarantee of high efficiency and high reliability in use.

2. High-speed and high-gloss spindle design. The spindle adopts five P4 precision bearings in the front three and the back two, labyrinth waterproof design and radiator type spindle box design to achieve the best waterproof and dust-proof effect. Use high-tech lubrication technology and unique sleeve. The structure spindle shows the best stability, ensuring the maximum axial rigidity, radial rigidity and machining accuracy. The servo spindle motor scheme is adopted to realize a wide range of automatic stepless speed regulation and indexing functions.

3. High precision, high speed and high rigidity ball screw and linear guide rail. The X and Z axes use Taiwan brand ball screw and linear guide rail, and the screw bearing uses SKF precision bearing. Large span between rails, displacement speed up to 25M/min, double pre-tensioning design is adopted at both ends of the screw rod to improve the accuracy and stability of the machine tool. The rotation of the two shafts is directly connected by the servo motor and the precision ball screw through the elastic coupling, with good stress and high positioning accuracy. It is equipped with a computer automatic lubrication system for forced lubrication. Ensure the long-term stability of the machine tool.

4. The control system uses the 630TA bus type CNC system independently developed and produced, and the servo motor uses the absolute value type, with high accuracy and good stability, and no need to return to zero when starting.

5. The hydraulic station adopts variable displacement pump, motor, solenoid valve and air cooling device, which has low noise and low oil temperature.

6. The heat exchanger is used in the electrical control box to rapidly exhaust the hot gas in the electrical box, maintain the constant temperature in the box, and make the control system operate stably.

7. The beautiful full protective cover has good waterproof performance, and the movable door can be opened easily and freely

| Case Study Configuration: LC-36 installs the Hydraulic collect, Y-Axis Side Milling Device, and C-axis function* Workpiece: Turning a Φ32 small impeller from Φ32mm brass bar material Machining Process: Turning, threading, Facing, Milling, Parting. Turning Duration: within 30 seconds  |

Previous page

Next page

Previous page

Next page

Product message