WKTEC 630TA Turning CNC System

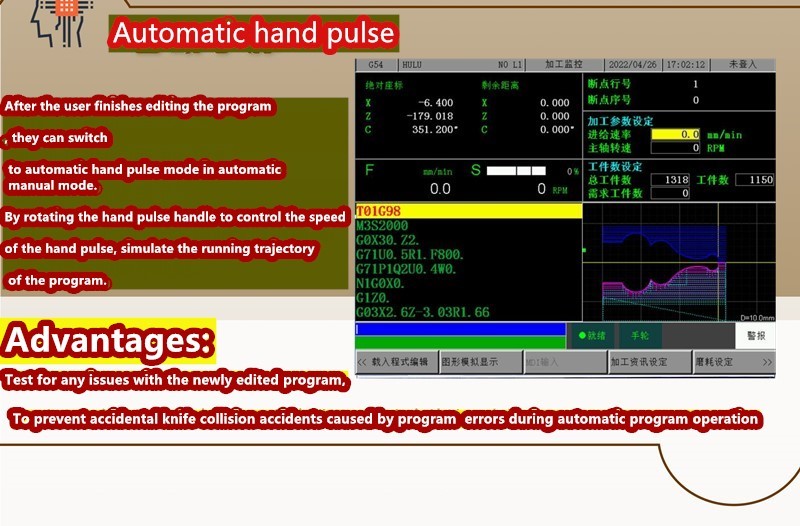

2-4 axes, lathe controller, incremental/485 absolutevalue, hydraulic turret/four station electric tool holder, supporting A/B macro program, spindle indexing, polygonal cutting, polar interpolation, cylindrical interpolation, automatic tool measurement,linear angle programming function, drilling cycle function, tool tip radius compensation, graphic simulation, spindle accurate stop positioning, handwheel simulation function

Classification:

CNC System

Hotline:

Product description

WKTEC 630TA Turning CNC System

WKTEC 630TA Turning CNC System supports 2-4 axes, X and Z axis control, with 0.001mm interpolation accuracy, supporting linear, circular, elliptical, and parabolic interpolation

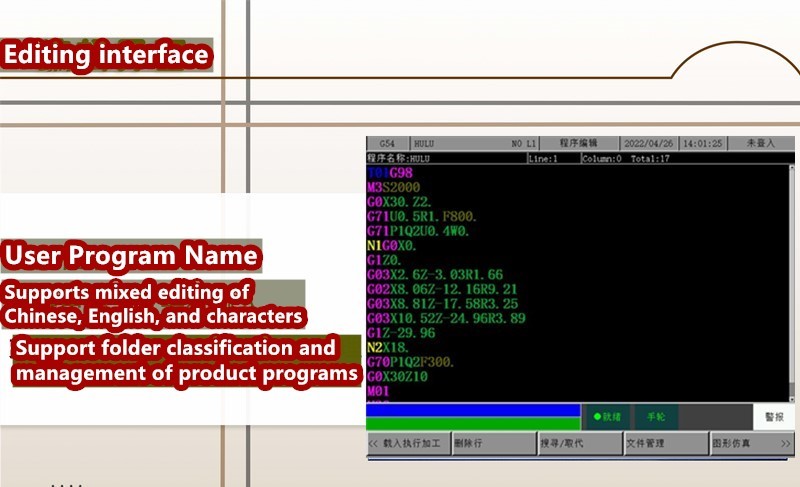

2 channels of 0-10v analog voltage output, supporting dual spindle control Support statement based macro instruction editing and macro program calls with parameters

Equipped with USB interface, greatly facilitating the copying of machining programs and the import and export of system parameters

Capable of turning various threads, thread tail length, and thread insertion angle can be set Equipped with various composite cycle functions such as tapping, deep hole drilling, grooving, inner and outer cylindrical surfaces, and end face cyclic processing

Equipped with various specialized functions such as chamfering function, automatic repeated feeding, conditional waiting.

What is CNC System?

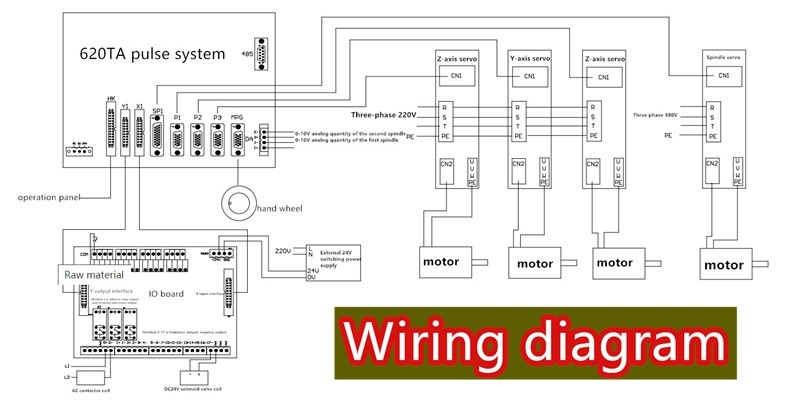

handwheel simulation function, and graphic simulation function. The control core is composed of a 32-bit high-speed CPU and a very large scale programmable integrated chip, μ M-level precision control, 800x600 dot matrix TFT true color LCD display, Chinese operation interface, simple and intuitive operation. What is a pulse type CNC system? The pulse type CNC system 620TA has a USB drive

handwheel simulation function, and graphic simulation function. The control core is composed of a 32-bit high-speed CPU and a very large scale programmable integrated chip, μ M-level precision control, 800x600 dot matrix TFT true color LCD display, Chinese operation interface, simple and intuitive operation. What is a pulse type CNC system? The pulse type CNC system 620TA has a USB drive

| Number of control axes | 2 Axis |

| Minimum programming | 0.001mm |

| Display | 8.4 inch color screen |

| interface | USB+RS232 Communction Port |

| Maximum programming | ± 99999.999mm |

| Top speed | 30m / min |

| Feed speed | 0.001-15m / min |

| Spindle functions | Gear, dual analog control, rigid tapping |

| Pre-reading function | Short line preprocessing 10,000 lines |

| Function | ATC+PLC and macro function |

| Encoder lines | Any setting |

| User macro program | Yes |

| Our Services | 12 Months warranty;Provide professional CNC solutions; |

| Compensation function | Knife compensation, between compensation, screw compensation, radius compensation |

| Security function | Emergency stop, hardware travel limit, various stored travel checks, axis interlock, data backup and recovery |

| Thread function | 1) Curved ordinary thread (following the spindle) 1 flexible tapping |

| 2) Single/multiple metric inch straight thread, tapered thread and face thread, equal pitch thread and variable pitch thread | |

| 3) The length, angle and speed characteristics of thread run-out can be set by program and parameters | |

| 4) Thread pitch: 0.001mm~ 500mm (metric) 0.06 thread/inch~25400 thread/inch (imperial) |

Features:

Features:

1) 800x600 8.4 inch real color LCD displayer

2) Support PLC and macro function, and automatic tool exchange function

3) 128MB Memory , 100Mb user store room,

4) 5MHz Pulse Output Frequency, The max speed is 300m/min, feeding speed is 150m/min

5) Adapted servo spindle can realize spindle continous position,rigid tapping,rigid screw processing

6) High anti-jamming switch power(220VAC -> 24VDC & 5VDC)

7) Built-in many plc programs,which can be edited freely.

8) With USB interface,it supports file operation in flash disk,system configuration and software upgrade

9) Display in chinese or english,which can be selected by parameter.

10) Analog voltage output of 0~10V in two channels,support double spindles

11) 32 bits high performance, low power consumption industrial grade ARM microprocessor.

12) Basic I/Os : 40*24 ,can be edited freely

13) cutter offset : C

14) English menu, program and interface, full screen edition

Application:

CNC lathe machinery; lathe center; wood working machine; numerically control grinder; MTDC applied to engraving CNC machine.

Frequently asked questions

Can you make OEM products?

Yes, we can do OEM. Materials, colors, and styles can be customized, and we will suggest the basic quantity after discussion.

How about further development?

All open PLCs and freely customizable macros.

Can you customize printing with our logo?

Yes, we can print your personal logo according to your requirements.

How many different types of products does your company produce?

We now have over 300 products. We have a strong OEM advantage, as long as you provide us with actual products or ideas you want, we will manufacture them for you.

What services can we provide?

1. Acceptable delivery terms: FOB, CFR, CIF, EXW, FAS, CIP, FCA, DDP, DDU, DAF;

2. Accepting payment currencies: USD, EUR, CAD, HKD, RMB;

3. Payment types accepted: T/T, L/C, D/P D/A, credit card, PayPal, Western Union remittance, cash, custody; 4. Oral English: English, Chinese, Spanish, Japanese, Portuguese, German, Arabic, French, Russian, Korean, Italian, etc.

6. What is your delivery time?

The general delivery time is 4-6 days after receiving the order confirmation. If we have the goods, it only takes 1-2 days.

7. Do you provide samples? Is it free?

If the sample value is low, we will provide free samples and the shipping fee will be charged by us. But for some high-value samples, we need to charge sample fees.

If you have any other questions, please feel free to contact us as shown below.

Hot Tags: WKTEC 630TA Turning CNC System

Controller,China, suppliers, factory, manufacturers, price, cheap, wholesale low price,quotation, datasheet, specs, specification,2 axis cnc controller board,china famous 2 axis cnc control system manufacturer for drilling machine,plc+atc 2 axis cnc console control 3axis lathe and milling machine gsk tool cnc controller system panel,4 axis absolute cnc controller,cnc milling controller,cnc machine controller

Previous page

Previous page

Product message