WKTEC 630TA-5 Absolutely type 5 Axis CNC Lathe & Turnning Controller

WKTEC 630TA-5 5 axis absolutely type CNC lathe controller with WKTEC absolutely type servo engine &controller 1)ATC function: Electric Turret/Binary Turret/Servo Turret/Special Turret 2)Threading Cycle: Following Mode/Interpolate Mode 3)M2 communication turning machine cnc system ,4 axis cnc controller,lathe bus system with atc+plc

Classification:

Lathe CNC Controller

Hotline:

Product description

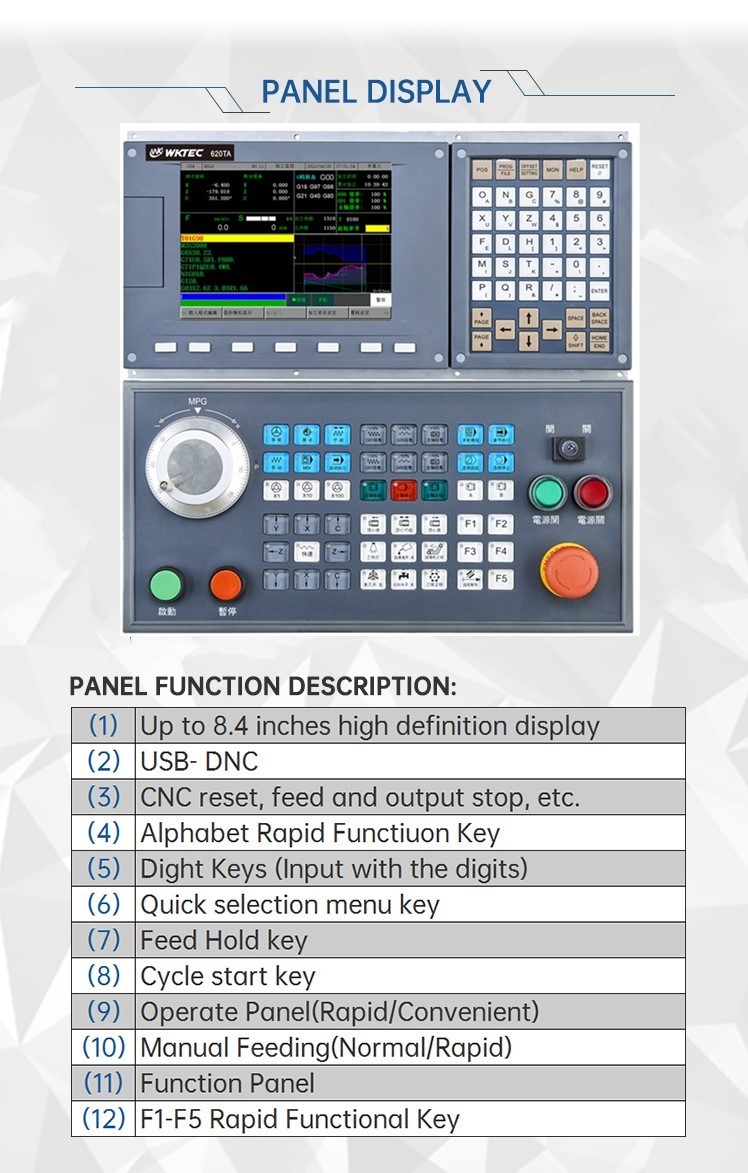

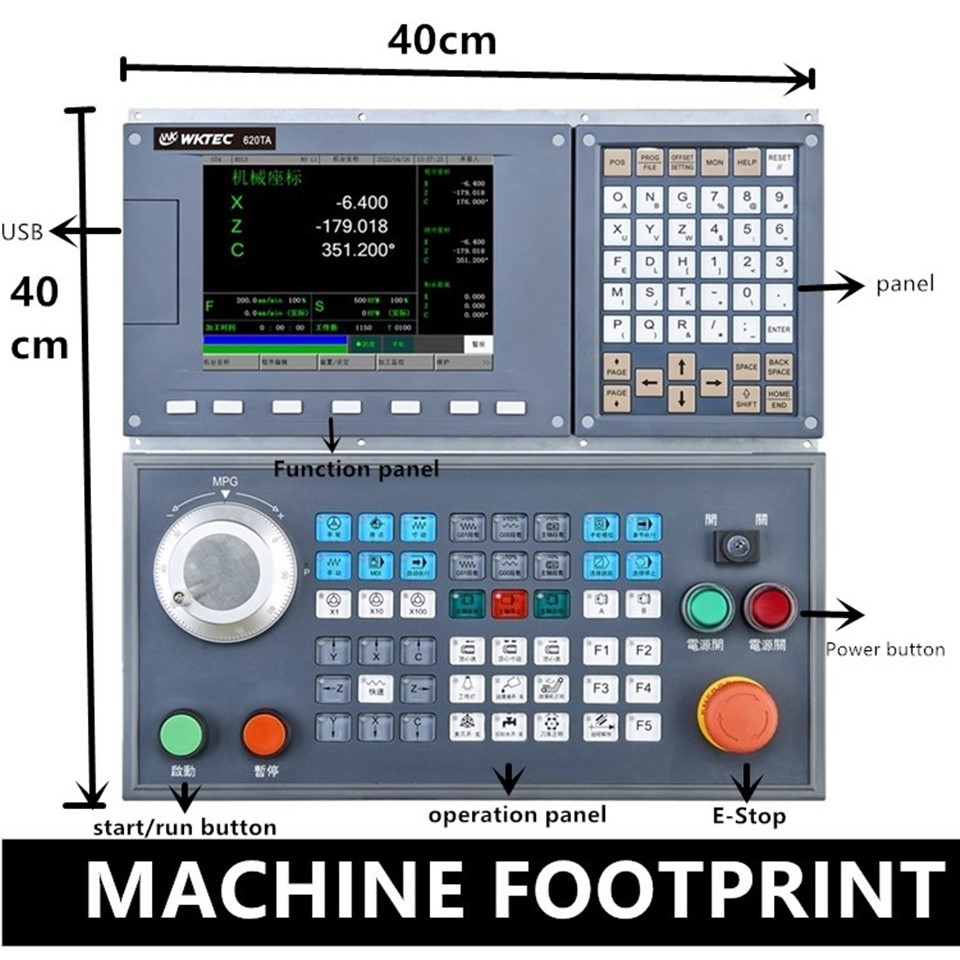

▶ Product Details---Main Panel

WKTEC 630TA-5 Absolutely type 5 Axis CNC Lathe & Turnning Controller

▶ Main Features:

WKTEC 630TA-5 Absolutely type 5 Axis CNC Lathe & Turnning Controller

1)ATC function: Electric Turret/Binary Turret/Servo Turret/Special Turret

2)Threading Cycle: Following Mode/Interpolate Mode

3) Support Dual analog voltage(0~10V) & C-axis for Spindle servo(M800)

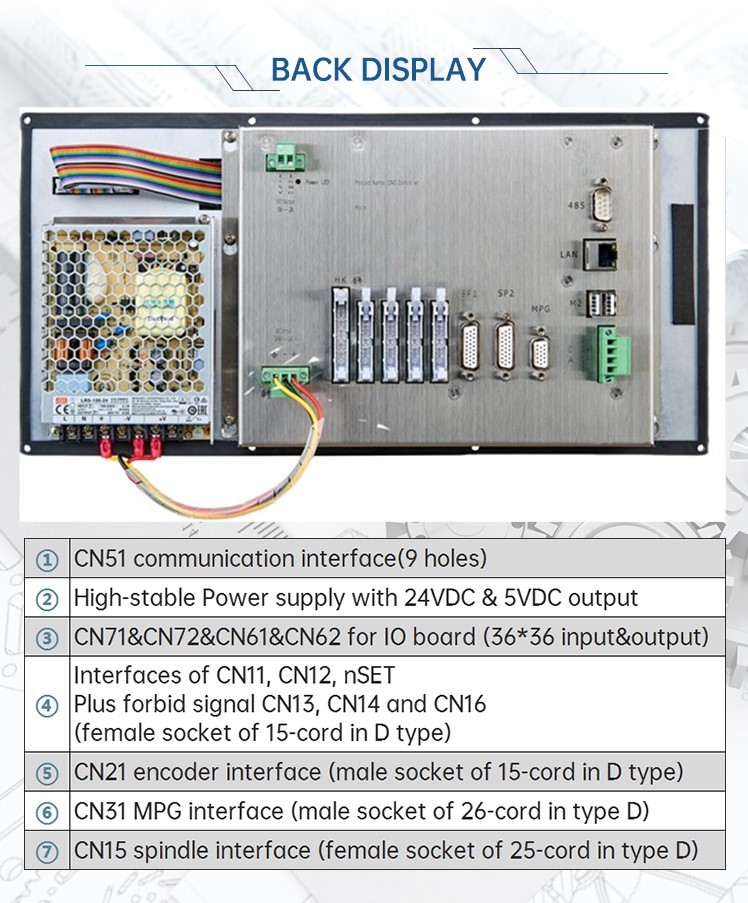

4) Support Stepper/Increment/Absolute/EtherCAT/Powerlink Servo for Feeding Axes

5) Scanning Function & Auto Tool Setter

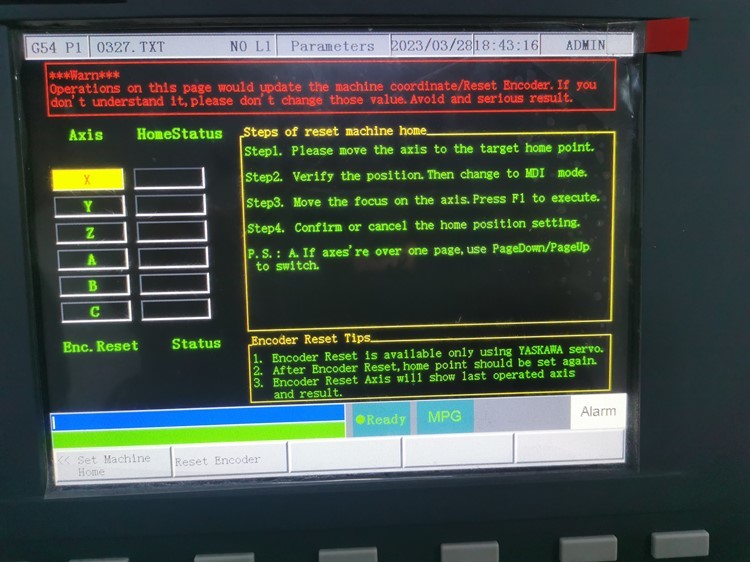

▶ Features:

1) 800x600 8.4 inch real color LCD displayer.

2) Support PLC and macro function, and automatic tool exchange function.

3) 64MB Memory , 32Mb user store room.

4) The max speed is 30m/min, feeding speed is 15m/min.

5)X and Z axis control, with 0.001mm interpolationaccuracy, supporting linear, circular, elliptical, and parabolic interpolation

6)2 channels of 0-10v analog voltage output, supporting dual spindle control Support statement based macro instruction editing and macro program calls with parameters

7)Equipped with USB interface, greatly facilitating the copying of machining programs and the import and export of system parameters

8)Capable of turning various threads, thread tail length, and thread insertion angle can be set Equipped with various composite cycle functions such as tapping, deep hole drilling, grooving, inner and outer cylindrical surfaces, and end face cyclic processing

9)Equipped with various specialized functions such as chamfering function, automatic repeated feeding,conditional waiting, etc

10)Open clock function, piece counting function, and time permission can be set when the device leaves the factory

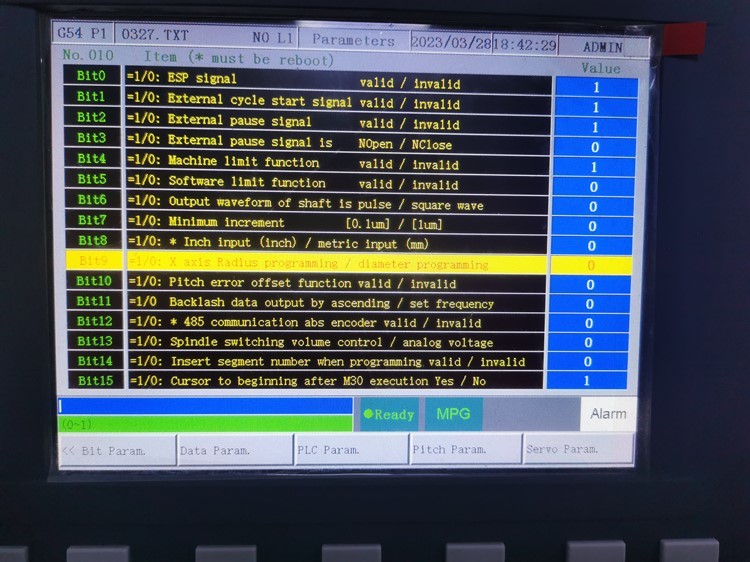

11)Electronic gear function. Can directly connect the motor to any pitch screw Embedded and open PLC, which can adjust parameters as needed to freely control the I/O port

12)Reverse clearance and pitch compensation functions maximize machining accuracy

13)Large program capacity: 32M bytes, capable of storing 480 processing programs.

▶ Application:

CNC lathe machinery; lathe center; wood working machine; numerically control grinder; MTDC applied to engraving CNC machine.slant bed cnc machine

Previous page

Product message